About Us

INFRASTRUCTURE

The Mysore Starch Manufacturing Company (Mysmaco) has designed and perfected the process for manufacturing Tamarind seed powder.

Today our infrastructure and machineries have been our core strength. Over the past years we have added much automated technology in field of tamarind seed powder manufacturing process with complete less maintenance free, less handling and delivering high quality final product and some of our machines are equipped with best USA and UK based technology to produce finest quality and even in the future we strive to continue to equip best machineries.

AS WE ALL KNOW “TECHNOLOGY CHANGE IN TIME”.

LAND, BUILDING AND MACHINERYThe Mysore Starch manufacturing company spanning over 118900Sqft and operates on 87120Sqft area has well equipped buildings and machineries.

The company has three major building attached to one and another under which all the manufacturing process takes place, each building has been designed uniquely to avoid cross contamination over different grades of tamarind seed products and also keeping in mind the packaging of final product.

further there is also separate building which is allotted for initial raw material storage and final product storage material purposes, the Building one is referred has unit one is equipped with double cleaning machinery where finest first quality of food and pharma grade of tamarind kernel powder are manufactured and packed, further the unit one building is an complete enclosed area where outside air and dust are stopped in entering the building. Building two is referred has unit two where tamarind seeds are thoroughly cleaned by not allowing the dust to pass on to next Buildings, further Sorted though conveyer belts and labours and finally broken down through machines and passed on to either unit one or unit three for final product. Lastly Building three is referred has unit three where large capacity of industrial purpose grade production takes place. So in view of above the Company constantly monitors and has taken many in-house steps to control the quality.

TESTING AND RESEARCH LAB

Our company has a research lab with testing instruments and equipments for checking Technical specification of products and also we test our product regularly from Tuv certificated labs for quality purposes.

MANUFACTURING PROCESS

The Mysore starch manufacturing company has a high production capacity to meet the requirements around the world for tamarind seed powder based products nevertheless the company produces different grades of tamarind kernel powder products at same time for different industrial applications and usages.

Black coated seed husk tamarind seeds -> white tamarind seeds -> white broken tamarind seeds -> Tamrind seed/kernel powder.

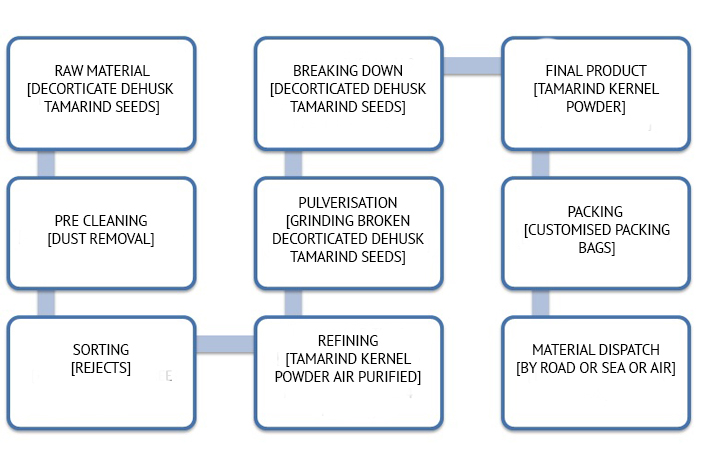

Tamarind Seed (Kernel) Powder (TKP) Manufacturing Process:

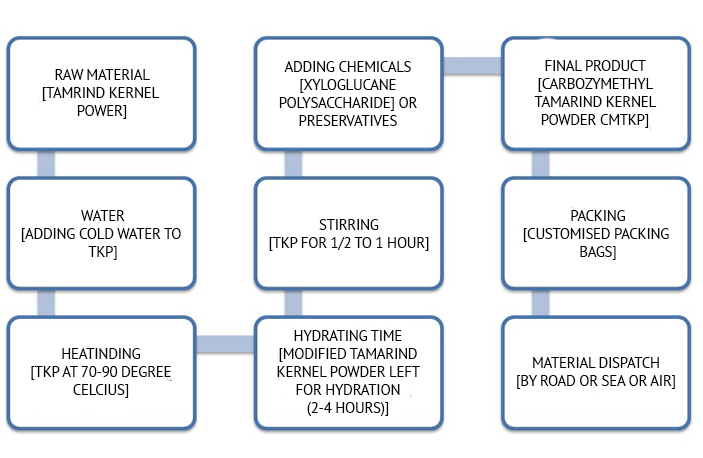

CARBOXYMETHYL TAMARIND KERNEL POWDER (CMTKP) MANUFACTURING PROCESS:

Final product:

Finest powder of Tamarind starch powder is achieved through perfect cleanly, grading, sorting and packed accordingly.